Hydronic specializes in air driven hydraulic pumps,

high pressure systems and power units.

Our product line includes miniature products for manifold mounting, complete off-the-shelf modular

power packs and a variety of models in between. Hydronic covers most flows and pressures for building

into sophisticated pumping systems with flows up to 6 gpm and hydraulic pressures up to 52,000 psi.

These products are well suited for traditional low horse power applications such as:

Pressure Sustaining

Intermittent Application

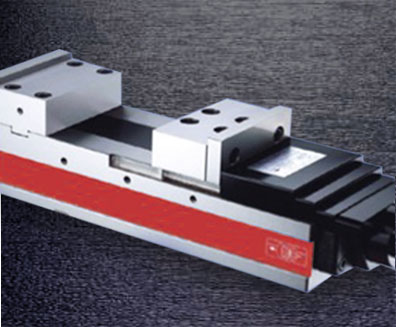

Work Holding

Hazardous Areas

Unlike other manufacturers, our pumps can be used with a variety of fluids in addition to hydraulic oil,

including brake fluid, Skydrol, water glycol and a number of others.